Pretty sure I do. Just recapped a portable mono. Don't think things went so well. The hard drive spins up now to full speed (thats new). The speaker crackles a little. But the screen display has not changed it patterns and it will not boot. No startup sound, etc. I did disconnect the hard drive in case it was pulling too much power. All cards out.

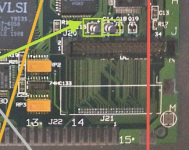

There are two caps near the programer switches. These I did not replace (missed em!). Like the others, they look sub-par. Would these have any play in the issue or do my soldering skill simple suck? Ugh...

There are two caps near the programer switches. These I did not replace (missed em!). Like the others, they look sub-par. Would these have any play in the issue or do my soldering skill simple suck? Ugh...