joethezombie

Well-known member

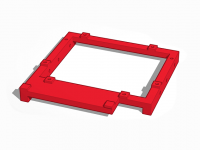

I've been working on a universal mount for v6 and v5 SCSI2SDs that will easily install in most classic Macs and most likely other computers, too. It looks like this:

The notch provides relief for the rather large plastic clips which hold the molex connector to the v5 boards. The raised mounts keep the solder side pins off the surface. You can use self tapping screws with your chosen pitch to thread the holes, then use nice screws to mount it. Be very careful with the v6 board, as the traces are very close to the holes. Use small head screws, consider a washer, and be very careful.

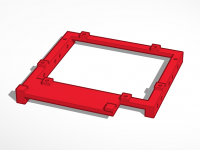

Here it is with the v6 card, on one of the aftermarket "slide" style HDD platforms that bolt above the floppy cage (there are holes on the bottom for surface mount applications):

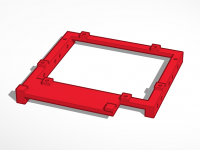

Here it is with the v5 card in a standard drive cage:

It also fits in my IIsi, IIfx, and Q700 cages.

I haven't tested it in a 500 series, but I'm 99.82% sure it will not line up with the edge connector.

The mount didn't work with one of my SE/30s, with the upside-down drive orientation (the holes didn't line up), so I created a new revision that I will try to print tomorrow at the library if I can fit in. If everything looks good, then I will attach the files here so you can print them out. If you have access to a 3D printer at your library, it's pretty cheap. I uploaded a version to Shapeways and it was about $17 including shipping, so that's pretty expensive for what could also be achieved with some cardboard. But it is a neat permanent solution.

The notch provides relief for the rather large plastic clips which hold the molex connector to the v5 boards. The raised mounts keep the solder side pins off the surface. You can use self tapping screws with your chosen pitch to thread the holes, then use nice screws to mount it. Be very careful with the v6 board, as the traces are very close to the holes. Use small head screws, consider a washer, and be very careful.

Here it is with the v6 card, on one of the aftermarket "slide" style HDD platforms that bolt above the floppy cage (there are holes on the bottom for surface mount applications):

Here it is with the v5 card in a standard drive cage:

It also fits in my IIsi, IIfx, and Q700 cages.

I haven't tested it in a 500 series, but I'm 99.82% sure it will not line up with the edge connector.

The mount didn't work with one of my SE/30s, with the upside-down drive orientation (the holes didn't line up), so I created a new revision that I will try to print tomorrow at the library if I can fit in. If everything looks good, then I will attach the files here so you can print them out. If you have access to a 3D printer at your library, it's pretty cheap. I uploaded a version to Shapeways and it was about $17 including shipping, so that's pretty expensive for what could also be achieved with some cardboard. But it is a neat permanent solution.

Last edited by a moderator: