-

Updated 2023-07-12: Hello, Guest! Welcome back, and be sure to check out this follow-up post about our outage a week or so ago.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reverse Engineering the Macintosh SE PCB & Custom Chips for 1:1 reproduction

- Thread starter Kai Robinson

- Start date

Kai Robinson

Well-known member

....and this batch of boards is dead, too. I'm pissed off right now. The inner copper layers of the rear I/O are bridged. I've checked the files i sent and there's nothing there that can cause it. +5v and GND are bridged somewhere. Even with no components, it's bridged.

Franklinstein

Well-known member

That's really unfortunate. Could one of the vias have caused it, or maybe one of the larger lugs at the rear of the board? Maybe if you have a sensitive tone generator and pickup you could potentially trace out the current flow to try to find where it connects or at least narrow your search a bit.

Kai Robinson

Well-known member

I'm looking over the board at serious magnification - DRC checks, test pads show no components bridging - it's a manufacturing issue. Nothing is connecting anything incorrectly. If it were a component, that'd be understandable, but this is a board level defect with the internal layers. If you cut the bridge connecting the ground planes, the rest of the board has no issues, its just the rear I/O - i'm going to totally re-do the cutout areas, just in case, and make them intersect stuff. I may relocate some of the filters by 39.6875uM just to make them clear the 'split' just right.

Bolle

Well-known member

Where did you have them fabbed? I never had any actual fabrication defects ever.

All boards go through electrical testing (at least at JLCPCB where I usually order my boards) so it really shouldn't happen at all.

You could try to connect a bench power supply and run a whole lot of power through the board to see where it starts to turn black to find out where the short is.

All boards go through electrical testing (at least at JLCPCB where I usually order my boards) so it really shouldn't happen at all.

You could try to connect a bench power supply and run a whole lot of power through the board to see where it starts to turn black to find out where the short is.

Kai Robinson

Well-known member

Unfortunately, the bench power supply is the thing i lack. A FLIR camera would also be good. They're being fabbed at JLCPCB - I'm happy to release the gerbers to someone if they want to check them over?

techknight

Well-known member

I have gerber utilties that I use to verify my board designs, so you can send the gerbers my way.

You know its in the I/O section in the rear? itll give me a place to start so I dont go crosseyed.

You know its in the I/O section in the rear? itll give me a place to start so I dont go crosseyed.

Kai Robinson

Well-known member

Yes - confirmed, there's no short outside of the split I/O section at the rear - , if you remove the link between them, the board will power up in the chassis as previously. I'll DM you with the Gerbers.

techknight

Well-known member

Ok

techknight

Well-known member

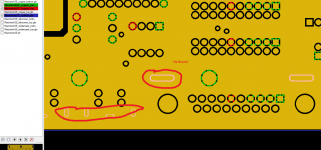

Kai Robinson

Well-known member

AAAAHA! OK, so that should solve the problem.

techknight

Well-known member

You might be able to just temporarily drill all those out.

techknight

Well-known member

Yea, need to make each of those holes a part of the circuit and connected to ground, so the layout engine knows what to do with them, and can do its thing.Was just going to say that... I was staring at VCC and GND layers and saw nothing but it jumped right at me when I activated the outline Layer.

quorten

Well-known member

I'm kind of wondering about the mention of ground connection, the Macintosh SE/30 schematic does say that hot and cold ground are connected together, is this also the same with the Macintosh SE or are they kept separate? I've assumed that the wire to the chassis connected it to protective ground on the AC plug and this was kept separate from the PSU common ground, but I haven't looked carefully to verify it.

techknight

Well-known member

There is no such thing as hot or cold ground unless your dealing with a power supply.

with a logic board, you have analog and digital grounds. Or, Filtered/Unfiltered grounds.

with a logic board, you have analog and digital grounds. Or, Filtered/Unfiltered grounds.

Kai Robinson

Well-known member

Rev 1.4c now in production - I know i can drill these boards, but i'd need to buy a drill for that...and to be honest, it's part of the process of prototyping - it's less expensive to spin up a batch of 10 more boards, than to get a dremel and whatnot - and probably just as quick to order.

Thanks to @techknight and @Bolle for helping with the Gerber evaluation - fingers crossed 3rd time is the charm! To the people waiting on a board - i thankfully hadn't sent out a faulty one yet.

I've received some donations in the past few weeks to help with the costs of the project, just need to go and get more passives, now!

Thanks to @techknight and @Bolle for helping with the Gerber evaluation - fingers crossed 3rd time is the charm! To the people waiting on a board - i thankfully hadn't sent out a faulty one yet.

I've received some donations in the past few weeks to help with the costs of the project, just need to go and get more passives, now!

Similar threads

- Replies

- 39

- Views

- 5K

- Replies

- 23

- Views

- 2K

- Replies

- 5

- Views

- 725