LaPorta

Well-known member

The next part is delicate: you can damage the very small connections between the upper circuit board and the LCD if you put too much pressure. Flip up the upper circuit board out of the way, and lift the back of the LCD housing away from the display panel itself:

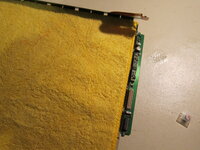

That will leave you with the bare panel and board containing the capacitors:

That will leave you with the bare panel and board containing the capacitors: