I mean.. there's not that many capacitors, sure there's a filtering cap for each chip, but they're almost all the same kinds. So it might be worth your time to hit digikey or jameco or some other place and buy a few dozen caps as needed and replace them all without waiting for the ESR meter, and you could save yourself future work by replacing them with ceramic or film caps as appropriate which are a bit more pricey but will last far far longer. (I won't say forever.)

You can use almost any cap as long as the capacitance is within 20% or so tolerance, and the voltage rating is what the part specifies or higher. They also need to be polar if the original is, or non-polar if the original is.

Thank you both for your help.

A while back I ordered a ESR meter and it arrived today (took absolutely forever but I'm glad that its finally here). So I tested the capacitors C33 and C46 two capacitors involved in some shape or form from what I can tell with the +5B2 trace (I could be wrong here). Both capacitors tested fine and were good according to the meter. I then check most of the larger (in physical size) axial electrolytics on the board also and they too were fine. I then compared the readings to a working 2/10 I/O board and the values obtained were very similar.

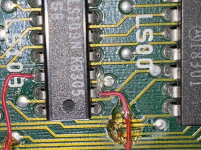

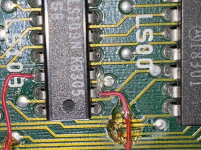

That's when I saw this...

Between pin 12 and 13 (if I remember correctly) on LS109 there is a small full break in the trace. The only explanation I could think of what's that the trace is not too damaged such that after the computer has been on it heats up a bit causing the copper to expand and then make contact. After patching this trace, at the moment (I feel as though I have to stress this because the machine almost caught me out with the whole parallel connector fiasco) it's working fine now and switching on and off normally. Again I am really not sure if what I have done is correct but it seems to have done the trick for now. I am very surprised that given the visual appearance of this I/O board that only one trace was broken due to the corrosion. I realise that if left untreated it's a ticking bomb, but the boards have been treated and their functioning state hasn't deteriorated further after 4 years of ownership of this machine.