-

Updated 2023-07-12: Hello, Guest! Welcome back, and be sure to check out this follow-up post about our outage a week or so ago.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Don't use 16V SOLID Tantalum on SE/30 Motherboards

- Thread starter JDW

- Start date

Brett B.

Well-known member

I have also done many boards with 16v caps. Zero failures that I can attribute to the components themselves - plenty that are directly my fault but that's another topic.

I'm curious if there is a true risk in doing this... what is the exact time before failure can occur? Are we talking hours? Hundreds of hours? Depends? I imagine most of us probably have our old computers powered on a minimal amount of time... I'd be shocked if any of mine see more than 5 or 10 hours of use per year. I hate to admit but most maybe get powered on for a few minutes and then put away for long periods of time... at that rate, if we're suspecting failure after even hundreds of hours, I'd have many years before I could expect failure. But if I'm going to have failure by fire at 10 hours, that is a problem.

As far as removing them goes - two irons, one on each side and a very steady hand.

I'm curious if there is a true risk in doing this... what is the exact time before failure can occur? Are we talking hours? Hundreds of hours? Depends? I imagine most of us probably have our old computers powered on a minimal amount of time... I'd be shocked if any of mine see more than 5 or 10 hours of use per year. I hate to admit but most maybe get powered on for a few minutes and then put away for long periods of time... at that rate, if we're suspecting failure after even hundreds of hours, I'd have many years before I could expect failure. But if I'm going to have failure by fire at 10 hours, that is a problem.

As far as removing them goes - two irons, one on each side and a very steady hand.

@Brett B. I think you hit the nail pretty close to center. The "danger", as I understand it, is a shortening of the life of the capacitor and one of the variables is how much time the cap spends at high voltage and temperature conditions. If a 16V cap only experiences 12 volts on occasional peaks, then it may not have its life shortened in a meaningful way. On the other hand, if it's used across the 12V rail and ground, that could be an issue.

My indirect experience is that I sold about 2000 47uF 16V caps and maybe 1500 47uf 20V caps for Macintosh recappings and have had zero complaints about failures -- so far. I started with five reels of 500 16V caps, but there are a couple of instances involving largish numbers of caps that I don't know for certain were used. So I rounded down to 2000 from 2500. After I ran out of those, I found the 20V caps and have been using those.

After reading this info, the next reel I get will be 25V. If I ever need another reel. Sales dropped off considerably a while back. Which is fine. It was never a money maker. More of a, "Here's the caps you need for folks who aren't comfortable ordering from big electronics suppliers." Back in 2007 and earlier, capacitor failure was not well known and most folks weren't comfortable with any part of the topic, from soldering to obtaining replacement parts.

My indirect experience is that I sold about 2000 47uF 16V caps and maybe 1500 47uf 20V caps for Macintosh recappings and have had zero complaints about failures -- so far. I started with five reels of 500 16V caps, but there are a couple of instances involving largish numbers of caps that I don't know for certain were used. So I rounded down to 2000 from 2500. After I ran out of those, I found the 20V caps and have been using those.

After reading this info, the next reel I get will be 25V. If I ever need another reel. Sales dropped off considerably a while back. Which is fine. It was never a money maker. More of a, "Here's the caps you need for folks who aren't comfortable ordering from big electronics suppliers." Back in 2007 and earlier, capacitor failure was not well known and most folks weren't comfortable with any part of the topic, from soldering to obtaining replacement parts.

JDW

Well-known member

Hrm... I've recapped quite a few boards with 16v tantalum caps. I'm worried that trying to desolder them with an iron will be riskier than just running them. Has anyone seen a 16v tantalum cap on an SE/30 fail?

A lot of people ask the same question when it comes to the fluid-filled electrolytic capacitors on computer parts that "most people" refuse to recap, and yet I made an 800K Floppy Drive Recapping video about that because you really do need to recap those drives too even though they aren't failing left and right due to failing caps. A lot of decisions about capacitors often comes down to consensus among peers, which in turn is driven by practical personal experience too I will admit, but the reality is this:

1. Operating a tantalum capacitor at a voltage higher than it's manufacturer recommended derating increases the likelihood of failure, and with SOLID tantalum that failure is a dead short and a flame that could burn nearby components and/or PCB traces.

2. No fluid-filled electrolytic capacitor has eternal life, and leaked fluid can wreak havoc on a circuit board. It's not only SMD electrolytic capacitors on an SE/30 or Mac Classic motherboard that leak either.

In other words, it's a matter of Risk Management. Like I mention in the Recapping Advice video linked in my opening post, I too have previously used (without thinking) 16V "476C" Solid Tantalum 47µF capacitors on a couple SE/30 motherboards, and thankfully have not had a burn-down yet; but that good news in no way magically lessens the likelihood of failure for the 4pcs of 47µF which see 12V on the SE/30 motherboard, even if countless others have used the 16V parts without issue thus far (and many have, actually).

Have you recapped hundreds of SE/30 boards with 16V? Is it best to recall them all? Being a realist and practical person, I will say "no." If I was an owner of one of those boards though, would I ultimately make the decision to remove the 4pcs that see 12V and replace them with either Polymer Tantalum or OS-CON? Yes, I probably would, the next time I had enough parts to order with Mouser to qualify for free shipping, even if I didn't use that SE/30 24/7. However, it's important to keep in mind that many Solid Tantalums fail at the time of Power-on as opposed to a machine in continual operation, which means there's actually more associated risk to the Solid Tantalums in powering the machine on/off often versus leaving it on.

Despite the risk, I am not going to run around like a chicken with its head cut off in panic about this truth. And the risk is a truth regardless of "I've never had a problem" style consensus. But at the same time, I am compelled to give it due consideration, especially if I have the means to properly desolder the parts in question. Some folks like hot air, but I personally prefer the Tweezer shaped soldering tip shown in my MicroMac DiiMO recapping video.

So if any of you, like @trag or myself, have used 16V parts in the past, just be sure to use 25V rated parts from now on. And if you want the safest part when it comes to voltage, use Polymer Tantalum, as it only has a 20% derating.

Lastly, for those of you lucky enough to own one of the rare socketed Daystar accelerators like I do, it's important to keep in mind that one of the Axial capacitors sits directly beneath the accelerator as shown below. The Axial in this photo is a 10mm diameter type. It touches the SMD components on the bottom of the accelerator and puts just a tad bit of pressure on it as a result. Using an 8mm diameter cap, similar to the stock cap, would eliminate that issue entirely.

Last edited by a moderator:

JDW

Well-known member

Below is some of the information I provide in the text description under my General Advice video...

Rather than give you a Mouser Cart for the SE/30 motherboard, I instead provide links below to individual capacitors on Mouser. That gives you freedom to choose a Can-shaped capacitor for a stock look, or your favorite tantalum. The links below also let you choose the proper lead spacing for C11, which varies by motherboard version (2 types).

There are ten 47uF caps on an SE/30 motherboard: C1, C3, C4, C5, C7, C8, C9, C10, C12, C13.

I dislike liquid electrolytes, so I personally won't use Polymer "Hybrid" Aluminum Electrolytics; but I listed that Hybrid cap because it technically will work fine and is superior to a regular aluminum electrolytic.

:b&w: For the "stock look," go with the "Panasonic OS-CON." They have the lowest ESR, but leakage is twice Polymer Tantalum.

:beige: Want the lowest Leakage Current? Go with the "Kemet SOLID 25V Mid-height."

If you want the safest Tantalum below, in terms of being safer from a voltage spike that might kill the cap, the "AVX Polymer 25V Full-height" is ideal, albeit a bit pricey. Even a 16V Polymer Tantalum is "safe" with the SE/30 motherboard's 12V though, so technically any of the Polymer Tantalums below are fine choices for that application.

If you want the safest Tantalum below, in terms of being safer from a voltage spike that might kill the cap, the "AVX Polymer 25V Full-height" is ideal, albeit a bit pricey. Even a 16V Polymer Tantalum is "safe" with the SE/30 motherboard's 12V though, so technically any of the Polymer Tantalums below are fine choices for that application.

47uF 16V Polymer Aluminum Electrolytic Caps:

47uF Tantalum Caps:

NOTE: CAN-shaped Polymer Aluminum Electrolytics like OS-CON have higher leakage current than Polymer Tantalum, and much higher leakage than Solid Tantalum or regular fluid-filled Aluminum Electrolytics. That leakage spec doesn't matter for the SE/30 MB, but is an issue in circuits where low power matters, like battery-powered devices.

Remaining 3 caps:

Choose only 1 of the following for C11 because there are 2 Lead Spacing variants (check your SE/30 motherboard to find out which you need):

There are 13 caps in total on the SE/30 motherboard: 10pcs of 47uF and 1pc each of 1uF & 470uF & 220uF. The 4pcs of 47µF which see 12V are: C3, C4, C9 & C10.

Rather than give you a Mouser Cart for the SE/30 motherboard, I instead provide links below to individual capacitors on Mouser. That gives you freedom to choose a Can-shaped capacitor for a stock look, or your favorite tantalum. The links below also let you choose the proper lead spacing for C11, which varies by motherboard version (2 types).

There are ten 47uF caps on an SE/30 motherboard: C1, C3, C4, C5, C7, C8, C9, C10, C12, C13.

I dislike liquid electrolytes, so I personally won't use Polymer "Hybrid" Aluminum Electrolytics; but I listed that Hybrid cap because it technically will work fine and is superior to a regular aluminum electrolytic.

:b&w: For the "stock look," go with the "Panasonic OS-CON." They have the lowest ESR, but leakage is twice Polymer Tantalum.

:beige: Want the lowest Leakage Current? Go with the "Kemet SOLID 25V Mid-height."

47uF 16V Polymer Aluminum Electrolytic Caps:

- United-CC HYBRID! CAN-shape: https://bit.ly/3piGizK

- Nichicon CAN-shape: https://bit.ly/3nNl50j

- Panasonic OS-CON CAN-shape: https://bit.ly/37IlZWj

- Wurth CAN-shape (Cheap but High Leakage!): https://bit.ly/3phJyvc

- Murata Flat-shape (High Leakage! Harder to Solder!): https://bit.ly/3rh03tf

47uF Tantalum Caps:

- AVX Polymer 16V Full-height: https://bit.ly/3nJ8nzR

- Kemet Polymer 20V Short (harder to solder): https://bit.ly/3aCu7ta

- AVX Polymer 25V Short (harder to solder, but cheaper than Full-Size below): https://bit.ly/3mqIJhP

- AVX Polymer 25V Full-height: https://bit.ly/3aHCvrH

- Kemet SOLID 25V Mid-height: https://bit.ly/3riiC0d

NOTE: CAN-shaped Polymer Aluminum Electrolytics like OS-CON have higher leakage current than Polymer Tantalum, and much higher leakage than Solid Tantalum or regular fluid-filled Aluminum Electrolytics. That leakage spec doesn't matter for the SE/30 MB, but is an issue in circuits where low power matters, like battery-powered devices.

Remaining 3 caps:

- C6: 1uF 50V Polymer Tantalum: https://bit.ly/3pjk3cU

- C2: 470uF Axial: https://bit.ly/38tPlXF

Choose only 1 of the following for C11 because there are 2 Lead Spacing variants (check your SE/30 motherboard to find out which you need):

- C11 (for 20mm lead-spacing holes): 220uF Axial Cap (8mm diameter): https://bit.ly/3pivCkm

- C11 (for 33mm lead-spacing holes): 220uF Axial Cap (10mm diameter): https://bit.ly/3rmTVzC

There are 13 caps in total on the SE/30 motherboard: 10pcs of 47uF and 1pc each of 1uF & 470uF & 220uF. The 4pcs of 47µF which see 12V are: C3, C4, C9 & C10.

thanks to the info in the previous thread I went with the polymer can caps for that stock look:

it was a complete success, even the original HDD that would not boot started to work just fine after the recap:

I also did the psu and crt chassis so the system will be ready for the next 30 years LOL

thanks all for the info and especially JDW for the cap recommendations :b&w:

it was a complete success, even the original HDD that would not boot started to work just fine after the recap:

I also did the psu and crt chassis so the system will be ready for the next 30 years LOL

thanks all for the info and especially JDW for the cap recommendations :b&w:

Last edited by a moderator:

I agree that it, if you have not already recapped your Mac, it would be wise to use 25v caps instead of 16v due to the negligible increase in price. However, I believe that your conclusions regarding the risk of using 16v caps are overstated:

I don't know the series resistance of the circuit that these SE/30 capacitors are in, nor do I know whether these SE/30 capacitors are exposed to similar surges as in the test. Without this information, it seems premature to use this particular statistic to suggest that 16v capacitors are at "too high" a risk of failure - perhaps they are at higher risk of failure than 25v capacitors would be, but it's not clear from this statistic that this difference would be of any practical significance. Remember also that this statistic is for capacitors with 50% derating and no derating at all. In the SE/30 circuit, the capacitors are at 25% derating.

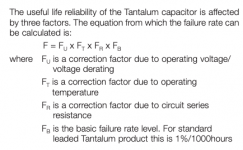

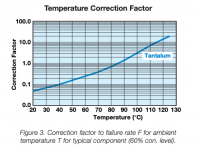

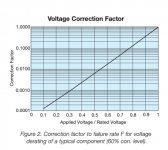

Furthermore, when examining steady-state failures, it becomes clear that the failure rate scales exponentially with voltage, not linearly (figure 2):

As figure 2 shows, the correction factor with a 25% derating is an more than an order of magnitude smaller than the correction factor for a capacitor with no derating. (Yes, the correction factor for a capacitor with a 50% derating is even better, but again, there are diminishing returns here - not clear that this difference is of practical significance).

This correction factor is for the steady-state rather than dynamic situation. As you noted:

Moving back to the steady-state situation, as here we can obtain some quick-and-dirty failure rate estimates.

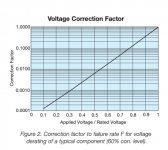

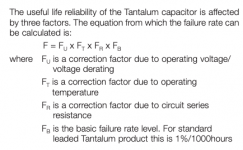

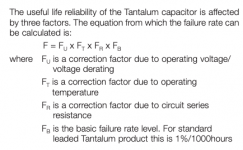

We have the following equation:

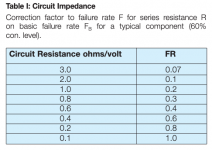

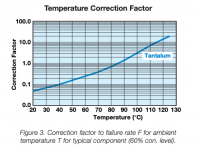

We have from Figure 2 above that F_u, the voltage correction factor for a 16v cap with a 12v applied voltage is 0.08. F_t is obtained from Figure 3:

I don't know what the ambient temperature is for these capacitors. I'm guessing it isn't 85C. Nevertheless, let's assume it is 85C, and obtain an upper bound estimate of the failure rate. Then F_t is 1.00.

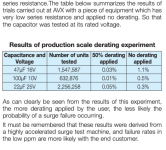

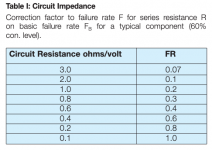

Again, I don't know what the circuit resistance in ohms/volt is for the SE/30. To form an upper bound estimate, I'll assume it's 0.1, so F_R is 1.00.

Finally, we have a standard failure rate F_B of 1%/1000hrs.

Thus, we obtain an upper bound estimate of .08 * 1.00 * 1.00 * 1%/1000HRS, or .08%/1000Hrs.

This is an extremely small failure rate, and it's an upper bound estimate: if anything, this overstates the real-world steady state failure rate of these capacitors. Recall we assumed that these capacitors experienced an ambient temperature of 85C...

In light of this, I think there is zero reason for anyone who has already replaced these capacitors with 16V tantalum capacitors to desolder and replace them with 25V capacitors. As far as I know, nobody has experienced damage to their computer from using 16V capacitors in this circuit. The list of people who have experienced damage to their logic boards from a lifted pad during recapping is a significantly longer one.

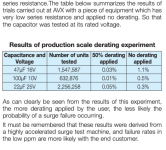

This is true, but why omit the context, page 19 of the PDF?:As shown in Table 4 on page 7 of this AVX Technical Document, the failure rate of 47uF 16V Solid Tantalum capacitors with a recommended 50% voltage derating stands at about 0.03% versus 1.1% for no voltage derating

I don't know the series resistance of the circuit that these SE/30 capacitors are in, nor do I know whether these SE/30 capacitors are exposed to similar surges as in the test. Without this information, it seems premature to use this particular statistic to suggest that 16v capacitors are at "too high" a risk of failure - perhaps they are at higher risk of failure than 25v capacitors would be, but it's not clear from this statistic that this difference would be of any practical significance. Remember also that this statistic is for capacitors with 50% derating and no derating at all. In the SE/30 circuit, the capacitors are at 25% derating.

Furthermore, when examining steady-state failures, it becomes clear that the failure rate scales exponentially with voltage, not linearly (figure 2):

As figure 2 shows, the correction factor with a 25% derating is an more than an order of magnitude smaller than the correction factor for a capacitor with no derating. (Yes, the correction factor for a capacitor with a 50% derating is even better, but again, there are diminishing returns here - not clear that this difference is of practical significance).

This correction factor is for the steady-state rather than dynamic situation. As you noted:

Suppose similar behavior (failures scale exponentially with voltage) occurs in the dynamic situation. The capacitors in the SE/30 see some derating as they are at 12v/16v. In this scenario we'd expect the failure rate of 47uF 16V Solid Tantalum capacitors with a 25% derating to be much, much closer to 0.03% than 1.1% (and remember, those figures are derived from a "highly accelerated surge test machine" and failure rates by the end consumer are expected to be lower).As shown in Table 4 on page 7 of this AVX Technical Document, the failure rate of 47uF 16V Solid Tantalum capacitors with a recommended 50% voltage derating stands at about 0.03% versus 1.1% for no voltage derating

Moving back to the steady-state situation, as here we can obtain some quick-and-dirty failure rate estimates.

We have the following equation:

We have from Figure 2 above that F_u, the voltage correction factor for a 16v cap with a 12v applied voltage is 0.08. F_t is obtained from Figure 3:

I don't know what the ambient temperature is for these capacitors. I'm guessing it isn't 85C. Nevertheless, let's assume it is 85C, and obtain an upper bound estimate of the failure rate. Then F_t is 1.00.

Again, I don't know what the circuit resistance in ohms/volt is for the SE/30. To form an upper bound estimate, I'll assume it's 0.1, so F_R is 1.00.

Finally, we have a standard failure rate F_B of 1%/1000hrs.

Thus, we obtain an upper bound estimate of .08 * 1.00 * 1.00 * 1%/1000HRS, or .08%/1000Hrs.

This is an extremely small failure rate, and it's an upper bound estimate: if anything, this overstates the real-world steady state failure rate of these capacitors. Recall we assumed that these capacitors experienced an ambient temperature of 85C...

In light of this, I think there is zero reason for anyone who has already replaced these capacitors with 16V tantalum capacitors to desolder and replace them with 25V capacitors. As far as I know, nobody has experienced damage to their computer from using 16V capacitors in this circuit. The list of people who have experienced damage to their logic boards from a lifted pad during recapping is a significantly longer one.

Last edited by a moderator:

I agree that it, if you have not already recapped your Mac, it would be wise to use 25v caps instead of 16v due to the negligible increase in price.

In light of this, I think there is zero reason for anyone who has already replaced these capacitors with 16V tantalum capacitors to desolder and replace them with 25V capacitors. As far as I know, nobody has experienced damage to their computer from using 16V capacitors in this circuit. The list of people who have experienced damage to their logic boards from a lifted pad during recapping is a significantly longer one.

Nice analysis. I felt like I was reading an engineering text book again -- and I mean that in a good way. Clear writing, little or no wasted verbiage, well organized.

One set of "test" machines to consider might be the ones in which Apple installed solid tantalums. The IIfx, Q700, a few others. I'm not sure our sampling is valid, since it amounts to "Have you heard anyone complain about...", but I can't recall anyone telling stories about the Apple installed caps failing. I can't remember off the top of my head what voltage rating they used, and I don't know what voltage they see in their circuits though. It might bear more investigation.

JDW

Well-known member

I agree that it, if you have not already recapped your Mac, it would be wise to use 25v caps instead of 16v...

This is an extremely small failure rate...

In light of this, I think there is zero reason for anyone who has already replaced these capacitors with 16V tantalum capacitors to desolder and replace them with 25V capacitors. As far as I know, nobody has experienced damage to their computer from using 16V capacitors in this circuit. The list of people who have experienced damage to their logic boards from a lifted pad during recapping is a significantly longer one.

Thank you for the extra analysis. I think that adds something important to this discussion, and nothing I'm about to say in any way undermines that.

In terms of low-resistance paths, C10 sees incoming +12V from the PSU while C9 sees -12V from the PSU, while C3 & C4 see 11V or so (in accordance with my testing) via the SONY sound chips, regarding which we have no datasheets and therefore cannot say exactly what goes on internal to those chips. So the lowest resistance paths would be C9 & C10. Because they get hit with off-board voltages, C9 & C10 are technically the most vulnerable to voltage spikes.

Of course, I have already considered the low failure rate prior to writing my previous posts, which is why in my earlier post I said there was no reason to run around like a chicken with its head cut off in a state of panic. But I don't necessarily agree that replacing caps on a recapped board will necessarily result in a lifted pad if you do it correctly and with the right tools. To argue against replacing a cap over the potential for a lifted pad would in effect be an argument against recapping in general. At the end of the day, it's a personal choice.

Also, the fact that you, me, Trag and everyone else in this thread do not personally know of anyone who has experienced a burned down 16V Solid Tantalum in a 12V circuit doesn't guarantee burned Tantalum caps used in a vintage board recap do not exist. The fact remains that the failure mode of SOLID Tantalum is a dead short and a flame that can no only burn the capacitor itself but also nearby components and/or traces. It is because of that especially harsh failure mode that we take serious consideration of the voltage derating. We also must consider that there are applications in which it is recommended to derate SOLID Tantalum at 1/3 its rated voltage, despite the "low failure rates" as have been noted. I have only been speaking about the standard 50% voltage derating.

Also, you said in your opening sentence that you agree that it would be wise to use 25V caps instead of 16V (meaning, "SOLID" obviously) and that there is a small but non-zero failure rate, and then you closed by saying there is "zero reason" to replace a recapped board. As long as the failure rate is non-zero, the "reason" to consider replacement of caps which see voltages higher than their derating cannot also be zero. So in fact, there is a reason to do it, however small one argues with data that reason may be. One could argue it not signifiant enough to be necessary, and that goes back to my chicken with its head cut off message. There's no need to panic. But those who want extra peace of mind can replace those 4 caps (C9, C10, C3, C4) on the SE/30 motherboard, assuming they are not afraid of lifting a pad.

In conclusion, this is all about erring on the side of safety in accordance with manufacturer specified voltage derating guidelines in spite of how low the risk may be as per failure data. As I said before, I would NOT recall every recapped board that uses 16V SOLID Tantalum to recap them if one has done that as a business. But in light of the facts and data presented, we can all agree that using 25V SOLID Tantalum or 16V (or higher) rated POLYMER Tantalum (or OS-CON, which has no voltage derating), is the most prudent choice moving forward on future recapping jobs on the SE/30. This thinking should be applied to the Mac Classic and other machines as well, whenever Tantalum is used for replacement capacitors.

Thank you again for your thoughtful and detailed analysis, Michael! It's much appreciated.

@keropi6k6 Your recap looks great. That board seems very clean too, almost like you used an ultrasonic cleaner on it. Great job!

MrFahrenheit

Well-known member

If a stock cap was 2200µF, you would not make a wise choice if replacing it with a 47µF capacitor, even if in your testing that 47µF cap seems to work. The voltage rating of a replacement capacitor is flexible, but unless you are an engineer with access to the original schematics, you cannot so easily say that a substantial chance in Capacitance would be a good idea for the circuit as a whole. The best rule of thumb is to never change the Capacitance when recapping, especially when in doubt about how much capacitance is actually necessary.

Using higher voltage replacement caps is nothing exclusive to the SE/30. Using higher voltage SOLID Tantalum capacitor is critically important, for "derating" reasons my video explains in detail.

The Macintosh I'm referencing with a 2200uf capacitor being replaced with 47uf is the Macintosh LC. The first run of Macintosh LC computers had a large through-hole capacitor spec'd at 2200uf. All of the motherboards produced, through the end of the manufacture, have a through-hole space and SMD space for a capacitor at this location. Subsequent boards (after the first run) issued by Apple with no apparent change in design replace this same capacitor with a 47uf, 16v SMD capacitor. I have replaced several 2200uf capacitors with 47uf capacitors on these boards without any noticeable issue.

My question is, why would Apple place a 2200uf capacitor and later replace it themselves with a 47uf capacitor, and how would this affect the performance of the capacitor and the machine? What is the danger of using capacitors with a higher capacitance number? I've never been able to figure this one out, and I cannot find any information online about the 2200uf and 47uf capacitors and the reasons.

aeberbach

Well-known member

@MrFahrenheit Such disparity between values suggests that component is to lower power supply ripple. It was common for “just in case” layouts to be made especially then when a PCB revision was much more expensive and physical space less important than now. If they could buy power supply ‘A’ for $X, then the cost of a 2200uF was warranted. If they could buy power supply ‘B’ for $Y, then the cheaper capacitor was used.

(it’s interesting to take a basic power supply, like AC rectified with diodes in a full-wave arrangement and see what happens to ripple using an oscilloscope as a capacitor across the rails gets larger. Basically it gets smaller as capacitance gets larger.)

@JDW I meant to say yesterday - great information! I found myself travelling in an area of bad cell coverage. It’s hard and time consuming to extract useful information from data sheets and present it so well.

(it’s interesting to take a basic power supply, like AC rectified with diodes in a full-wave arrangement and see what happens to ripple using an oscilloscope as a capacitor across the rails gets larger. Basically it gets smaller as capacitance gets larger.)

@JDW I meant to say yesterday - great information! I found myself travelling in an area of bad cell coverage. It’s hard and time consuming to extract useful information from data sheets and present it so well.

Last edited by a moderator:

JDW

Well-known member

Supplementing the excellent thoughts of @aeberbach, I do find it interesting that such a large capacitance was used in the first place. The difference between 47µF and 2200µF is huge. When we talk about "ripple" in this particular case (rising and falling voltage), we are most likely talking about having a large enough capacitance to ensure there are no major drops in voltage that would potentially cause the motherboard to freeze or produce an error. Picking 2200µF indicates to me that some pretty major voltage drops were experienced on those early board revisions, and rather than do the normal thing an use multiple smaller-value caps in parallel (which adds the capacitance while reducing the total ESR), they decided to go with one big cap (which has fairly low ESR due to the sheer capacitance size of the capacitor). If those big voltage drops that warranted use of a 2200µF capacitor on the motherboard were due to a lackluster early revision power supply, then the ability to use a smaller 47µF cap in place of the 2200µF cap would seem to be contingent upon using a later revision PSU that had a more stable output or a different motherboard layout that added more capacitance elsewhere. Voltage instability must have been the reason to use 200µF because I find it hard to believe Apple engineers would have chosen 2200µF only to later say, "Hey! 47µF works too!"

Since the original design called for a 2200µF capacitor, there would theoretically be nothing wrong with continuing to use that same large capacitance even with a newer revision voltage-stable power supply. But using a smaller cap would mean that it would not be able to maintain the voltage level if a sustained voltage drop appear on that voltage rail, regardless of cause. If 47µF really does work long-term, then I would say that 100µF or 220µF would work too, assuming you can find a 16V SMD cap that will fit those pads.

I'm no expert on the LC, nor have I ever owned one. As such, it would be nice to see schematics to better understand what may be going on with that voltage rail and see how it connects to the power supply.

@aeberbach, it is indeed time consuming and troublesome to glean the right information from data sheets. That's why when I make recapping videos specific to a particular board, I provide a Mouser Cart in the text description. My newest video is only providing general advice, which means I show how to navigate Mouser and mention some pitfalls when choosing caps by yourself. I added the SE/30 motherboard only as one example of how to go about picking capacitors. As you can see, there are many choices that will work just fine, but there are also some choices that are best to avoid. Picking the best capacitors is a complex subject for most people and only gets easier with time and experience. But even then, you still must make time to pour over the data sheets. That's hard for folks who lack an eye for detail. I suspect most of them will likely prefer to pay somebody else to recap their machine. While that's all fine and well, I like to encourage people to try the DIY approach because you might be able to save some money and you don't have to worry about trusting your prized vintage machine in the hands of somebody you don't know.

Since the original design called for a 2200µF capacitor, there would theoretically be nothing wrong with continuing to use that same large capacitance even with a newer revision voltage-stable power supply. But using a smaller cap would mean that it would not be able to maintain the voltage level if a sustained voltage drop appear on that voltage rail, regardless of cause. If 47µF really does work long-term, then I would say that 100µF or 220µF would work too, assuming you can find a 16V SMD cap that will fit those pads.

I'm no expert on the LC, nor have I ever owned one. As such, it would be nice to see schematics to better understand what may be going on with that voltage rail and see how it connects to the power supply.

@aeberbach, it is indeed time consuming and troublesome to glean the right information from data sheets. That's why when I make recapping videos specific to a particular board, I provide a Mouser Cart in the text description. My newest video is only providing general advice, which means I show how to navigate Mouser and mention some pitfalls when choosing caps by yourself. I added the SE/30 motherboard only as one example of how to go about picking capacitors. As you can see, there are many choices that will work just fine, but there are also some choices that are best to avoid. Picking the best capacitors is a complex subject for most people and only gets easier with time and experience. But even then, you still must make time to pour over the data sheets. That's hard for folks who lack an eye for detail. I suspect most of them will likely prefer to pay somebody else to recap their machine. While that's all fine and well, I like to encourage people to try the DIY approach because you might be able to save some money and you don't have to worry about trusting your prized vintage machine in the hands of somebody you don't know.

MrFahrenheit

Well-known member

I have two IIfx machines with Apple-installed tantalum caps. One of them was experiencing strange behavior. Freezing, slowness, power on failures.Nice analysis. I felt like I was reading an engineering text book again -- and I mean that in a good way. Clear writing, little or no wasted verbiage, well organized.

One set of "test" machines to consider might be the ones in which Apple installed solid tantalums. The IIfx, Q700, a few others. I'm not sure our sampling is valid, since it amounts to "Have you heard anyone complain about...", but I can't recall anyone telling stories about the Apple installed caps failing. I can't remember off the top of my head what voltage rating they used, and I don't know what voltage they see in their circuits though. It might bear more investigation.

All signs of capacitor failure like you find on a IIci for example (non-tantalums).

I recapped the board and discovered the 47uf 16v cap near SCSI was burned and such. The pad was so bad I ended up soldering the replacement onto the pads for the electrolytic can. The machine boots and runs perfectly now.

I also presently have a Q650 which uses all tantalum caps. It’s behaving badly. I initially thought it could be the PSU but I’ve changed the PSU and problems remain. I plan to recap it today to see if I can resolve the issue. I’ll let you know.

On the Q650, the 47uf caps are 10v. I plan to replace with the 16v I have.

ScutBoy

Well-known member

I recapped the board and discovered the 47uf 16v cap near SCSI was burned and such. The pad was so bad I ended up soldering the replacement onto the pads for the electrolytic can. The machine boots and runs perfectly now.

I also presently have a Q650 which uses all tantalum caps. It’s behaving badly. I initially thought it could be the PSU but I’ve changed the PSU and problems remain. I plan to recap it today to see if I can resolve the issue. I’ll let you know.

Interested to hear how this turns out...

MrFahrenheit

Well-known member

I examined the board and found that it used 47uf 10v caps. My plan was to replace with my stock of 47uf 16v caps. 6 extra volts, supposed to be safe. Then I looked at my other 650 board, and it came from factory with 47uf 6v caps!!Interested to hear how this turns out...

I’m like.... ...okay...

So I remove and replace the 47uf 10v caps with 47uf 16v. As I’m going around the board I discover a location at c10 where there is no cap. So I compare to my other 650 board. There’s a cap there. I look online. All boards I see have a cap there. It’s a 10uf 16v cap. It’s clearly not been removed or broken off, it was never there!!

Theres also 22uf 20v caps that I may need to replace. Now the only difference here is the other 650 board uses different spec caps for these too! It uses 22uf 16v caps. Very strange!

Both boards are -a revision. You’d think if they changed something it would result in a different revision.

So on to my problem. It now powers on with the usually gray screen and flashing question. Mouse works. SCSI does not. Looking at the board 10uf 16v are connected to SCSI. So I may need to replace the 10uf 16v caps as well. There are lots of them. I have 10uf 20v caps that have an ESR of 2.1ohms. I don’t know the specs of the ones on the board. Safe to just try? I don’t want to have to remove and resolder several times.

I do have 10uf 16v that are 3.1ohms and those are what I use in my Mac recaps usually.

So, so far it looks like at least some of the caps I’ve replaced might have been problematic. I’ll know for sure if I can recap the 10uf caps and it works again.

Should I just copy these progressions and start a new message or is this on topic with the topic here that I can just update here when I have an answer (one way or another)?

Last edited by a moderator:

JDW

Well-known member

Should I just copy these progressions and start a new message or is this on topic with the topic here that I can just update here when I have an answer (one way or another)?

I personally don't mind your posts here because what you have written thus far provides important proof which shows Solid Tantalum capacitors do fail even when chosen by big name manufacturers, and no doubt the voltage rating of those caps played a big role in those failures.

With that said, a new thread would bring more attention to your repair, so you might want to do that to ensure you get more eyes on it. I would encourage you to post updates in this thread which are specific to your Tantalum capacitor replacement though, as that info is relevant, in my opinion, despite the title of this thread being largely about the SE/30.

I examined the board and found that it used 47uf 10v caps. My plan was to replace with my stock of 47uf 16v caps. 6 extra volts, supposed to be safe. Then I looked at my other 650 board, and it came from factory with 47uf 6v caps!!

[snipped]

Great info, MrFahrenheit. Thank you for sharing it with us.

JDW

Well-known member

@JC8080 mentioned to me today that he recapped his Mac Classic motherboard with 16V Solid Tantalum capacitors. I downloaded the schematics and had a look. Unfortunately, C8 & C9 definitely have 12V across them; and C1, C2, C3 & C4 are all on the Sound chip which means some might see 12V as well, but that would need to be measured on a scope when switching on the power and when playing audio at full volume.

I marked all the capacitors in Yellow in these modified Bomarc schematics so you can see what I am seeing.

As such, our discussion in this thread applies to the Classic motherboard too, not just the SE/30 & IIfx.

I marked all the capacitors in Yellow in these modified Bomarc schematics so you can see what I am seeing.

As such, our discussion in this thread applies to the Classic motherboard too, not just the SE/30 & IIfx.

JDW

Well-known member

Actually, Jeff mentioned he has a Classic II, so I checked the 47µF & 10µF motherboard caps which are commonly replaced with Tantalum and highlighted all of those in Yellow in this modified Classic II Bomarc schematic. Specifically:

C3, C4, C5, C6, C7, C8, C10, C11, C12, C13, C14

C5 sees 12V through a 47µF resistor, but it should still technically be derated to 50% of working voltage.

C13 & C14 see 8V which means a 16V rated Solid Tantalum is OK.

The other caps are a part of the audio circuit. C10 & C4 might be vulnerable to spikes, so the peak voltage they see should be measured to confirm. Not sure what voltages C7 & C8 are seeing, so that too should be measured. The other caps should probably be fine when using 16V Solid Tantalum.

Again, what we are concerned about here is meeting the 50% voltage derating requirement.

C3, C4, C5, C6, C7, C8, C10, C11, C12, C13, C14

C5 sees 12V through a 47µF resistor, but it should still technically be derated to 50% of working voltage.

C13 & C14 see 8V which means a 16V rated Solid Tantalum is OK.

The other caps are a part of the audio circuit. C10 & C4 might be vulnerable to spikes, so the peak voltage they see should be measured to confirm. Not sure what voltages C7 & C8 are seeing, so that too should be measured. The other caps should probably be fine when using 16V Solid Tantalum.

Again, what we are concerned about here is meeting the 50% voltage derating requirement.

Last edited by a moderator:

aeberbach

Well-known member

I’m looking at C6, originally 1uF. I see on the schematic it is between pin 7 of UB11 and gnd, labelled SND-R-A/D. Below, UB10 has SND-L-A/D with a 0.1uF cap in the corresponding place. Does anyone have any more detail like a data sheet for these chips?

The smallest OS-CON capacitor available is 3.3uF, wondering if it could be used here. I really do like to replace with can style caps if possible - I have a perfect main board to recap and want it to look as original as possible.

The smallest OS-CON capacitor available is 3.3uF, wondering if it could be used here. I really do like to replace with can style caps if possible - I have a perfect main board to recap and want it to look as original as possible.

Similar threads

- Replies

- 16

- Views

- 893

- Replies

- 23

- Views

- 2K

- Replies

- 2

- Views

- 258

- Replies

- 18

- Views

- 1K