Trash80toHP_Mini

NIGHT STALKER

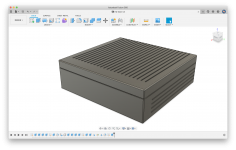

HRMMM . . . If you can print split sections of top and bottom for unification with ABS cement, mechanical fasteners and having a honeycomb support rib grid inside you may have modeled mold parts suitable for investment casting production? The seam lines between halves could be cleaned up giving a unified mold pattern.1. Printing in two parts, flat. Will involve generating support material... I'm just not sure how well this will go. Would look something like this. The bed isn't deep enough to print it as one piece so it would need to be two. The green on the left is support material - I'll do a smaller print to test that.

I've experimented with producing large panels using a similar process. Laying up an ABS glop of dissolved pipe connectors on a modeling clay form for eventual fiberglas reinforcement. I've an unlimited supply using waste from hull layup from a yacht builder I know for FRP parts. I came up with what's probably the ugliest CRT case quarter panel extant.

Reproducing smaller case sections using investment plaster negative molds (water soluble after casting a part) from your model should be investigated. If you purposely sectionalize a positive mold form with thin extensions along every rounded edge for sanding smooth afterward, it may also be possible to cast a multi-part mold reusable until it fails or inevitably wears out.

Dunno, gotta think it over outside my stream of drivel process. Time to make more coffee. :blink: